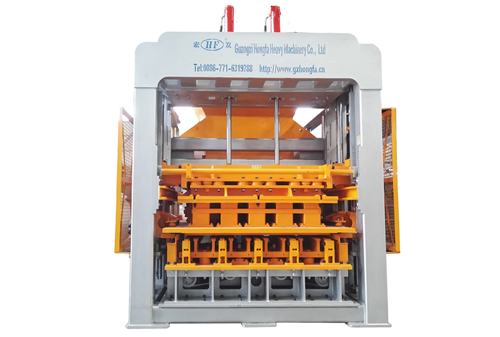

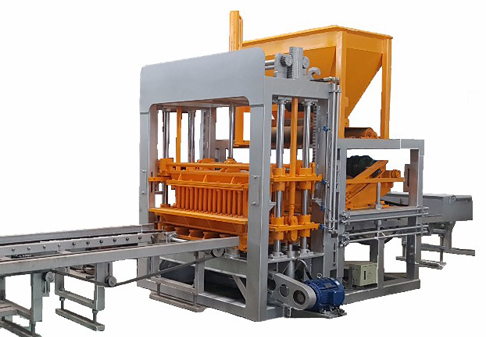

Concrete Block Making Machine, EPS Sandwich Wall Panel Production Line & AAC Plant Manufacturer Since 1990

Focus on Modern Building Material Machinery

Our Core Values

Large range of brick & EPS sandwich wall panel machine models are available in HONGFA to meet different status of your business.

Our Machine Customers Say

"Hongfa did great help for my wall panel project based on my ideas, they designed both unique machine and molds which are different from mainstream market specification. Thank you all guys for what you have done!!"

"Hongfa's block machine is very stable and easy to operate for my staff, now I am using semi-auto machine for my production, I will definitely come back to Hongfa oneday when I expand my capacity."